For over 60 years, Shackelford Machine has delivered mission-critical components for aerospace, defense, space, and industrial applications. Our family-owned expertise, cross-trained team, and lights-out machining capabilities ensure complex parts are produced with absolute accuracy, consistency, and reliability. When the stakes are high, we make sure your project is on-time, on-spec, and built to the highest standards.

Discuss your project with our experts today.

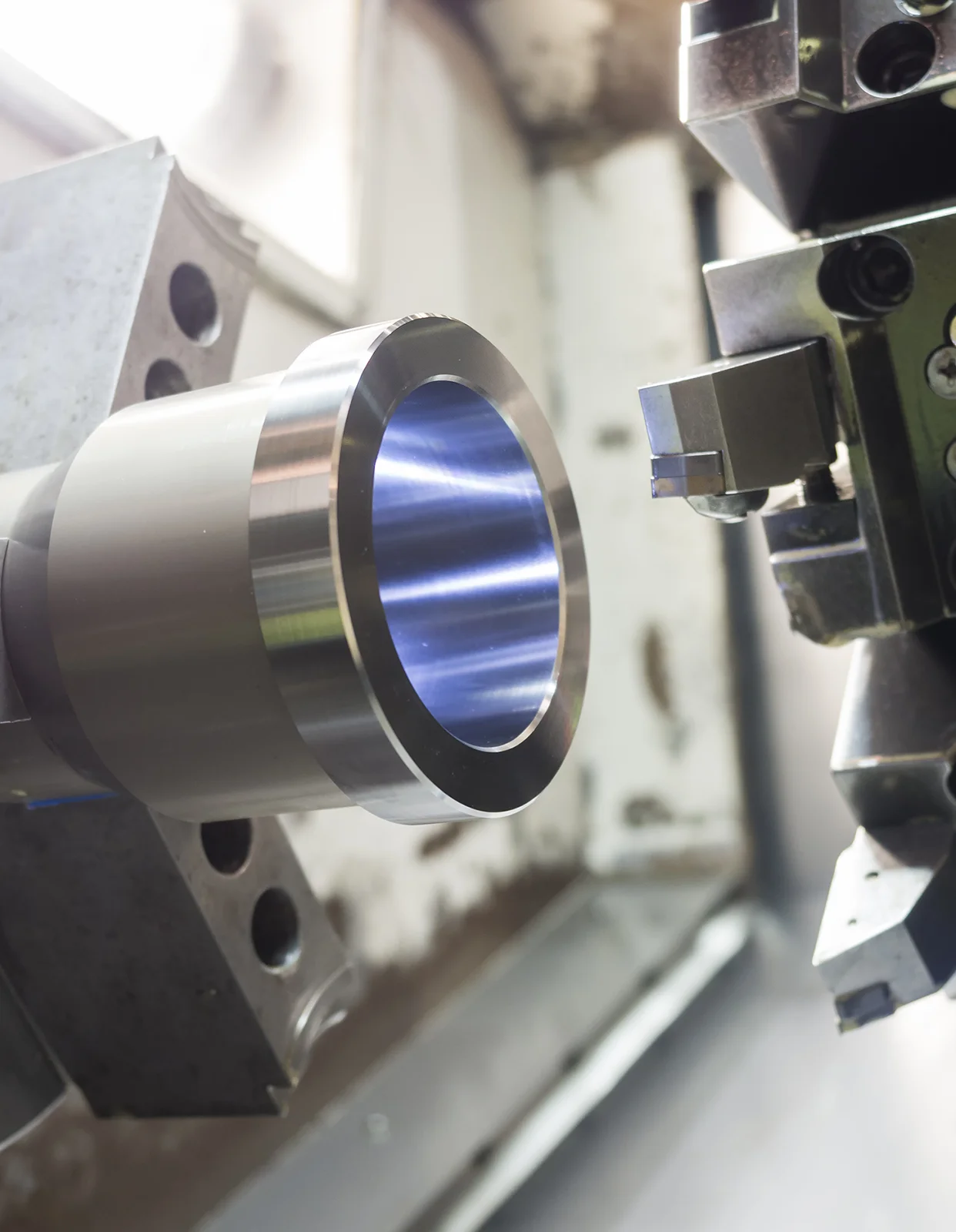

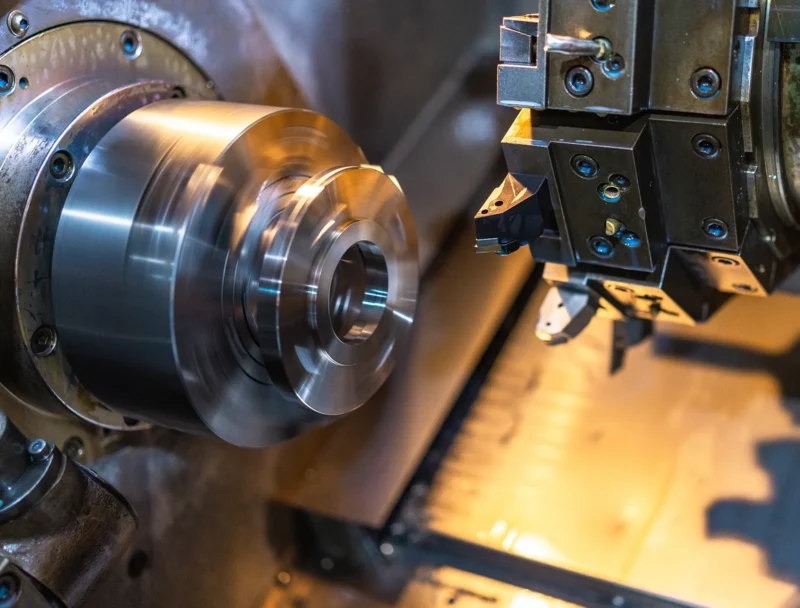

Our Turning Capabilities

Metals

Titanium, stainless steel, Inconel, nickel bronze, Toughmet, phosphor bronze, and other specialty alloys.

Part Sizes

Precision turning up to 32″ diameter, accommodating both large and small components.

Advanced Processes

Mill-turn integration, lights-out robotic operations, and close-tolerance machining for prototypes and production runs.

Engineering & Assembly Integration

Build-to-print assemblies, tolerance analysis, and turnkey solutions.

Industries We Serve

- Aerospace & Defense: ITAR-registered machining, assemblies, and engineering support

- Space Programs: High-precision components and complex assemblies for satellites, rockets, and rovers

- Industrial & Aftermarket: Durable parts, prototypes, and production runs

- Custom High-Tolerance Projects

Frequently Asked Questions

What metals can you turn?

We machine titanium, stainless steel, Inconel, nickel bronze, Toughmet, phosphor bronze, and other high-performance alloys.

What is the maximum size part you can turn?

Our precision lathes handle parts up to 32″ diameter, including both small and large components.

Can you handle complex geometries or multi-step machining?

Yes. Our mill-turn integration allows us to produce intricate, high-tolerance components efficiently in a single setup.

Do you offer lights-out CNC turning?

Yes. Our robotic systems enable unmanned overnight operations, maintaining tight tolerances and consistent quality.

Are your services certified for aerospace and defense projects?

Absolutely. We are AS9100 Rev D & ISO 9001:2015 certified and ITAR registered, ensuring compliant manufacturing for regulated industries.

Can you integrate turning with engineering and assembly support?

Yes. We provide turnkey solutions, including build-to-print assemblies, prototyping, and tolerance analysis.